Rethinking Sustainable Manufacturing: The Role of Remanufactured Parts

Whether it’s to be more environmentally conscious or business-friendly, the concept of sustainable manufacturing is evolving. Consumers and businesses are reevaluating their choices, seeking ways to reduce their carbon footprint and make responsible decisions regarding the environment. One area where significant strides in sustainability are being made, and often overlooked, is within the aftermarket industry through remanufactured parts.

Sustainable Manufacturing: What is It and Why Does It Matter?

Sustainable manufacturing is an approach to production that aims to minimize its environmental impact while optimizing economic efficiency and product quality. It’s a concept rooted in the belief that we can meet the demands of today without compromising the needs of future generations. It’s essential for a multitude of reasons.

- Climate Change Mitigation: Climate change is a global issue. Manufacturing can contribute to greenhouse gas emissions. Sustainable manufacturing seeks to reduce these emissions through cleaner processes and materials.

- Resource Conservation: Finite resources are consumed during traditional manufacturing. Sustainable manufacturing prioritizes resource conservation by recycling and reusing materials, ultimately reducing the need for virgin resources.

- Reduced Waste: Sustainable manufacturing reduces waste production by implementing lean production practices, recycling and remanufacturing.

- Economic Sustainability: Beyond environmental concerns, sustainable manufacturing also ensures economic viability by optimizing resource use, reducing costs and fostering innovation.

Leading Sustainability: The Aftermarket Industry

One remarkable way the aftermarket industry is leading the sustainability movement is through remanufactured parts. These parts offer consumers and businesses a sustainable option without compromising quality at an exceptional value

Quality and Value Combined

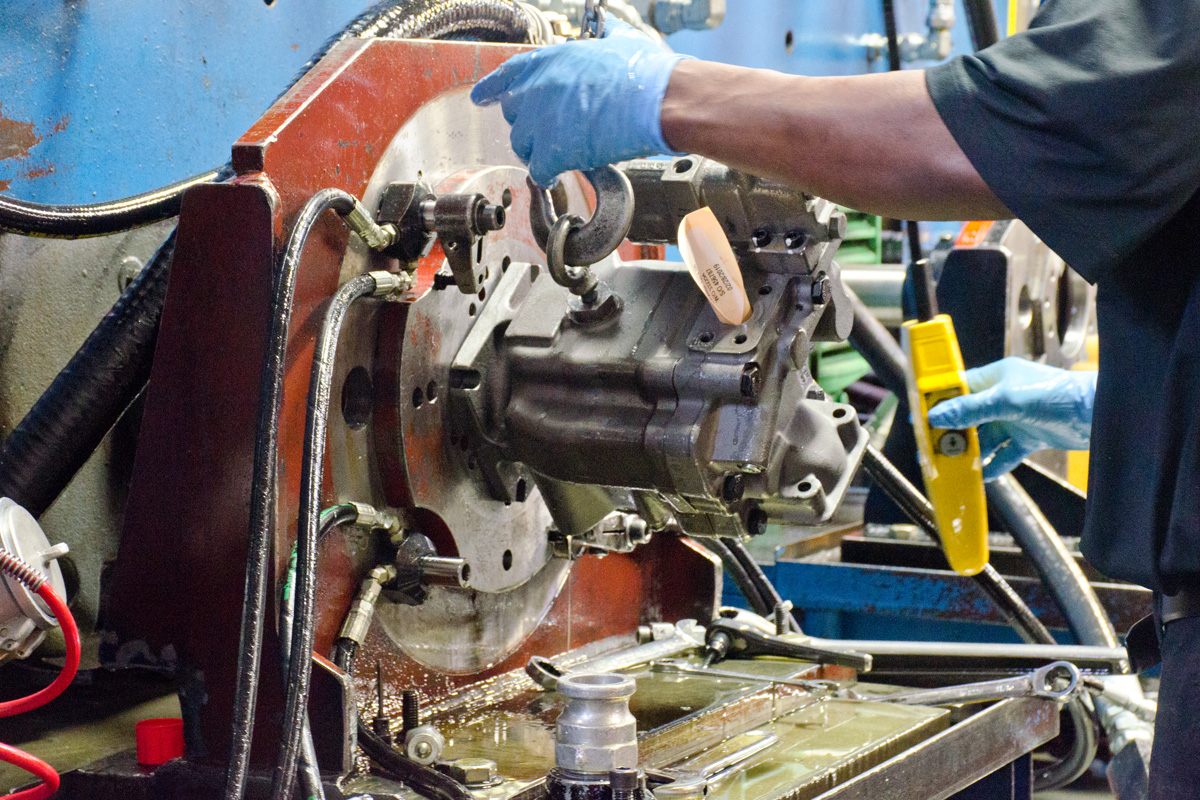

Leading manufacturers take pride in their meticulous processes, ensuring that these parts meet or exceed Original Equipment (OE) standard. It isn’t just a mere repair or refurbishment; it’s a comprehensive and sustainable industrial process.

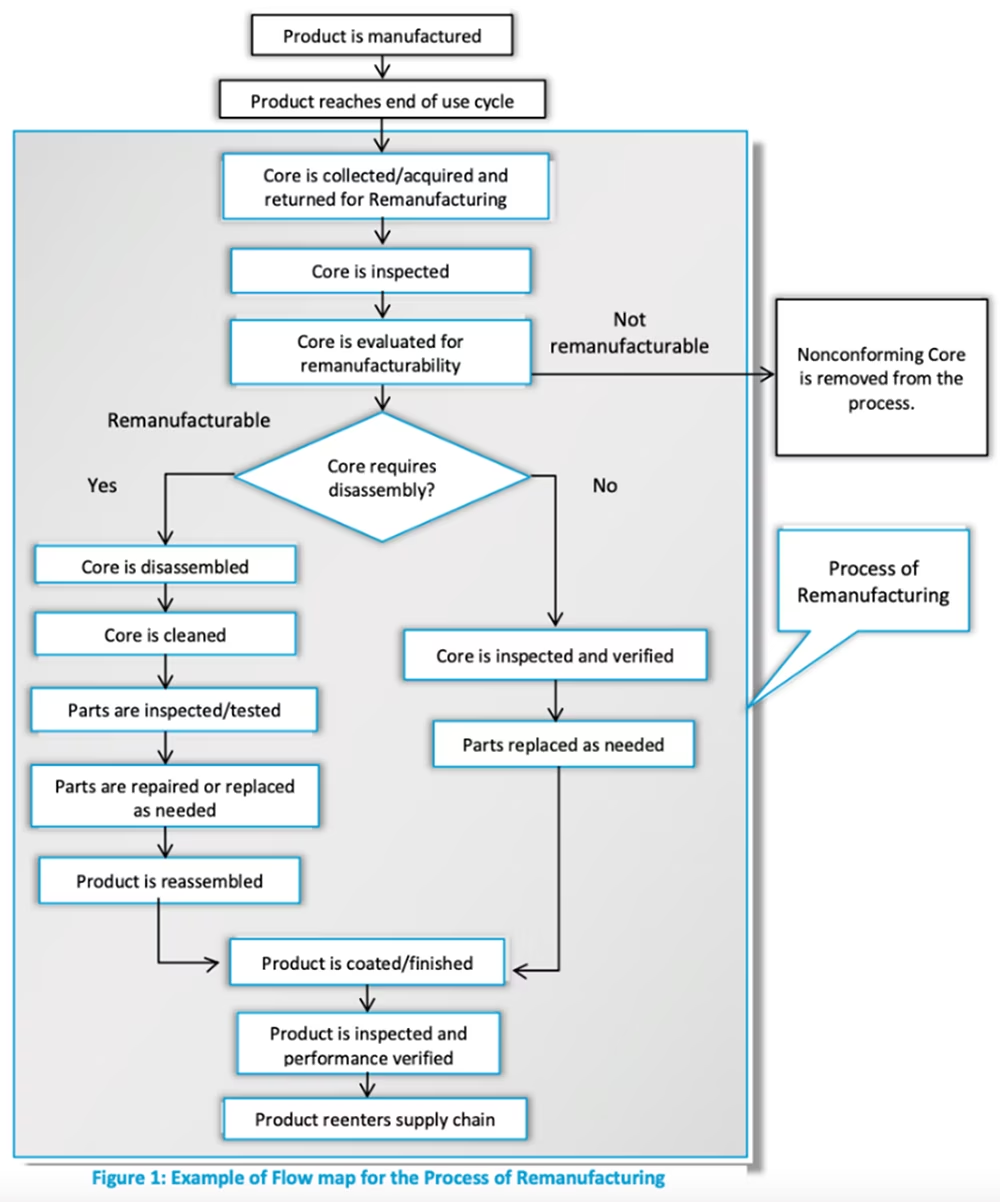

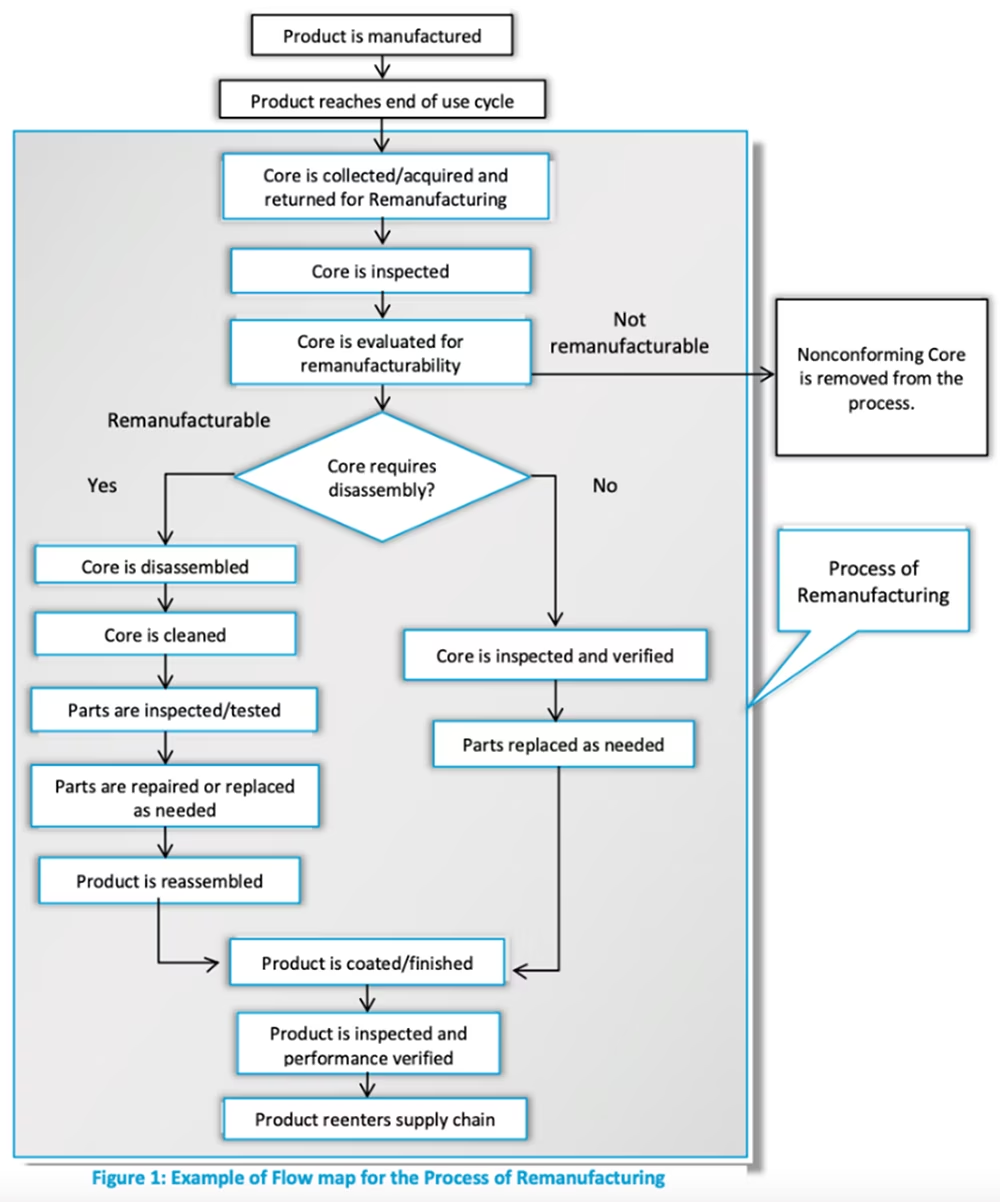

There are strict protocols that involve inspecting, disassembling, cleaning and reconditioning or replacing components. The units undergo rigorous testing against OE-tolerance specifications. The core of a part is disassembled to its individual components. All reusable parts are carefully cleaned, analyzed for failure modes and then reassembled using new components. In some cases, remanufacturers even address known OEM design issues by utilizing upgraded components that improve the original design.

Green Benefits of Remanufacturing

For consumers, a sustainably manufactured part can be an excellent economic value, providing like-new or better products at a lower cost. Equally important are the green benefits such as conserving energy, reducing manufacturing waste and recycling raw materials.

In short, remanufacturing is a sustainable process, not the same as simply repairing or refurbishing units.